» HSS DIN371 Threading Tap With Straight And Spiral Or Spiral Point Flute

DIN371 Threading Tap

Product Name: DIN371 Machine Tap

Thread Angle: 60°

Flute: Straight/ Spiral point/ Fast spiral Flute 35º/ Slow spiral Flute 15º

Material: HSS/ HSSCo5%

Coating: Bright/ TiN/ TiCN

Straight Flute

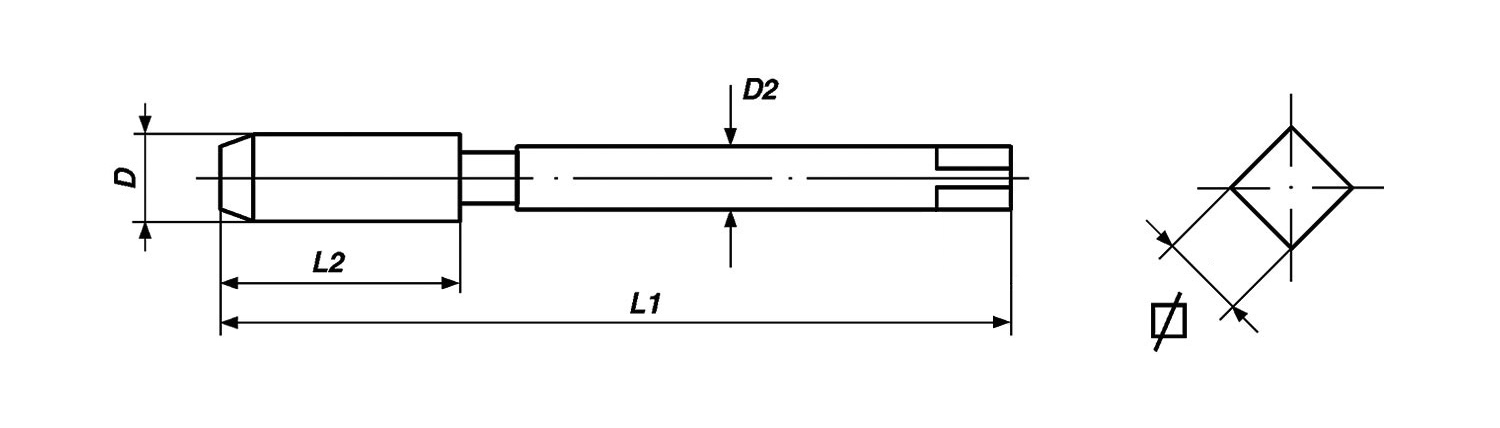

| SIZE (D) |

THREAD LENGTH(L2) |

TOTAL LENGTH(L1) |

SHANK DIA.(D2) |

SQUARE (a) |

HSS | HSSCo5% | ||

| Bright | TiN | Bright | TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3818 | 660-3831 | 660-3857 | 660-3870 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3819 | 660-3832 | 660-3858 | 660-3871 |

| M2.5×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3820 | 660-3833 | 660-3859 | 660-3872 |

| M2.6×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3821 | 660-3834 | 660-3860 | 660-3873 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3822 | 660-3835 | 660-3861 | 660-3874 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3823 | 660-3836 | 660-3862 | 660-3875 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3824 | 660-3837 | 660-3863 | 660-3876 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3825 | 660-3838 | 660-3864 | 660-3877 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3826 | 660-3839 | 660-3865 | 660-3878 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3827 | 660-3840 | 660-3866 | 660-3879 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3828 | 660-3841 | 660-3867 | 660-3880 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3829 | 660-3842 | 660-3868 | 660-3881 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3830 | 660-3843 | 660-3869 | 660-3882 |

Spiral Point

| SIZE (D) |

THREAD LENGTH(L2) |

TOTAL LENGTH(L1) |

SHANK DIA.(D2) |

SQUARE (a) |

HSS | HSSCo5% | ||

| Bright | TiN | Bright | TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3896 | 660-3909 | 660-3935 | 660-3948 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3897 | 660-3910 | 660-3936 | 660-3949 |

| M2.5×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3898 | 660-3911 | 660-3937 | 660-3950 |

| M2.6×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3899 | 660-3912 | 660-3938 | 660-3951 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3900 | 660-3913 | 660-3939 | 660-3952 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3901 | 660-3914 | 660-3940 | 660-3953 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3902 | 660-3915 | 660-3941 | 660-3954 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3903 | 660-3916 | 660-3942 | 660-3955 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3904 | 660-3917 | 660-3943 | 660-3956 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3905 | 660-3918 | 660-3944 | 660-3957 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3906 | 660-3919 | 660-3945 | 660-3958 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3907 | 660-3920 | 660-3946 | 660-3959 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3908 | 660-3921 | 660-3947 | 660-3960 |

Fast Spiral Flute 35º

| SIZE (D) |

THREAD LENGTH(L2) |

TOTAL LENGTH(L1) |

SHANK DIA.(D2) |

SQUARE (a) |

HSS | HSSCo5% | ||

| Bright | TiN | Bright | TiN | |||||

| M3×0.5 | 5 | 56 | 3.5 | 2.7 | 660-3974 | 660-3981 | 660-3995 | 660-4002 |

| M4×0.7 | 7 | 63 | 4.5 | 3.4 | 660-3975 | 660-3982 | 660-3996 | 660-4003 |

| M5×0.8 | 8 | 70 | 6 | 4.9 | 660-3976 | 660-3983 | 660-3997 | 660-4004 |

| M6×1 | 10 | 80 | 6 | 4.9 | 660-3977 | 660-3984 | 660-3998 | 660-4005 |

| M8×1.25 | 13 | 90 | 8 | 6.2 | 660-3978 | 660-3985 | 660-3999 | 660-4006 |

| M10×1.5 | 15 | 100 | 10 | 8 | 660-3979 | 660-3986 | 660-4000 | 660-4007 |

| M12×1.75 | 18 | 110 | 12 | 9 | 660-3980 | 660-3987 | 660-4001 | 660-4008 |

Slow Spiral Flute 15º

| SIZE (D) |

THREAD LENGTH(L2) |

TOTAL LENGTH(L1) |

SHANK DIA.(D2) |

SQUARE (a) |

HSS | HSSCo5% | ||

| Bright | TiN | Bright | TiN | |||||

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-4016 | 660-4023 | 660-4037 | 660-4044 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-4017 | 660-4024 | 660-4038 | 660-4045 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-4018 | 660-4025 | 660-4039 | 660-4046 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-4019 | 660-4026 | 660-4040 | 660-4047 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-4020 | 660-4027 | 660-4041 | 660-4048 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-4021 | 660-4028 | 660-4042 | 660-4049 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-4022 | 660-4029 | 660-4043 | 660-4050 |

Straight Flute DIN 371 Machine Tap

Application: Ideal for threading blind or through holes in steel, stainless steel, cast iron, and nonferrous materials. Its ground teeth and chamfer covering 2-3 threads make it suitable for thread depths less than 2 times the tap diameter (2d1).

Recommended Use: This type is particularly effective for hand tapping due to its straight flutes, offering stability and ease of use.

Spiral Point DIN 371 Machine Tap

Application: Designed for creating threads in through holes, this tap features ground teeth and a chamfer of 4-5 threads. It’s effective for thread depths up to 3 times the tap diameter (3d1) in steel, stainless steel, and cast iron.

Recommended Use: The spiral point pushes chips forward, making it ideal for through holes where chip evacuation is straightforward.

Fast Spiral Flute 35º DIN 371 Machine Tap

Application: This tap is designed for blind holes in steel, stainless steel, cast iron, and nonferrous materials with thread depths up to 2.5 times the tap diameter (2.5d1). The 35º fast spiral flute aids in efficient chip evacuation.

Recommended Use: Suitable for CNC machines where high-speed threading and precision are paramount.

Slow Spiral Flute 15º DIN 371 Machine Tap

Application: Like its fast spiral counterpart, this tap is used for blind holes in similar materials, but with a thread depth limit of 2 times the tap diameter (2d1). The 15º slow spiral flute offers controlled chip removal.

Recommended Use: Recommended for materials that produce long, stringy chips, ensuring a cleaner threading process.

Coating Options

Bright, TiN (Titanium Nitride), TiCN (Titanium Carbonitride): These coatings enhance the tap’s durability, heat resistance, and lubricity, thereby increasing tool life and performance in various materials.

Each of these taps can be specifically tailored for use in different machining environments, depending on the material, hole type, and desired thread depth. It’s crucial to select the right type of DIN 371 machine tap for each application to ensure optimal performance and longevity of the tool.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x DIN371 Machine Tap

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.